Contact us to request an exclusive pre-market trial at your plant

Martin Engineering’s pioneering remote monitoring system for conveyor belt cleaners. Follow us on LinkedIn to watch the install and keep updated on the latest news.

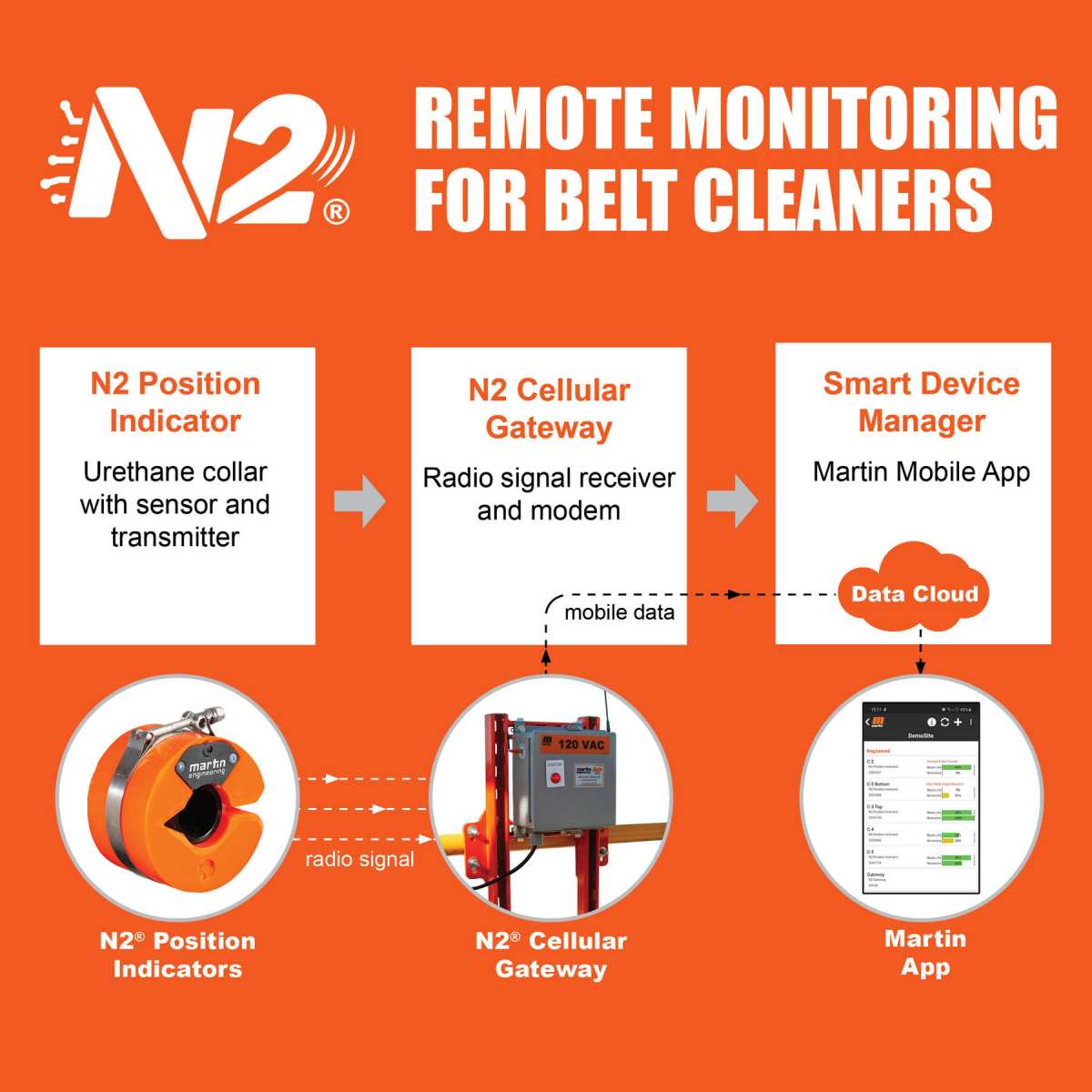

Our N2® Position Indicator removes safety risk, saves time and effort, and improves budgeting and inventory control – by sending performance data directly to your desktop or mobile device via an easy-to-use app.

|

Is your job about production in quarrying, mining or material processing? Do you run a complex plant with multiple conveyors over a wide area? Then remote monitoring for condition-based maintenance could be right for you. How do you know? Consider three statements: (1) I see the advantages of technology (rather than perceived problems or risks). Sounds like you? Then we’re confident you would benefit from Martin Engineering’s smart N2® remote monitoring system. Coming soon to Europe, Middle East, Africa and India, N2® predicts when conveyor belt cleaner blades need servicing or replacing, and keeps you updated via a mobile app or desktop dashboard. Send us an email now to find out more: N2_trial@martin-eng.com |

|

Deploying our pioneering N2® system to monitor conveyor belt cleaners remotely has meant working with some of the smartest technology service providers. We teamed up with two trusted Amazon Web Services (AWS) IoT partners – software solutions company Green Custard Ltd. and cellular connectivity specialists Eseye. Together we’ve developed a fully automated, seamlessly integrated and instantly secure cloud-based system that delivers super-reliable connectivity to allow maintenance managers to keep on top of belt cleaner performance anytime, anywhere without the need for physical inspection. As a result, following successful UK customer trials, we’re ready for rapid deployment of N2® to mining, quarrying and materials handling companies across Europe, the Middle East, Africa and the Indian subcontinent. To maximise your productivity using remote monitoring and predictive maintenance get in touch! |

|

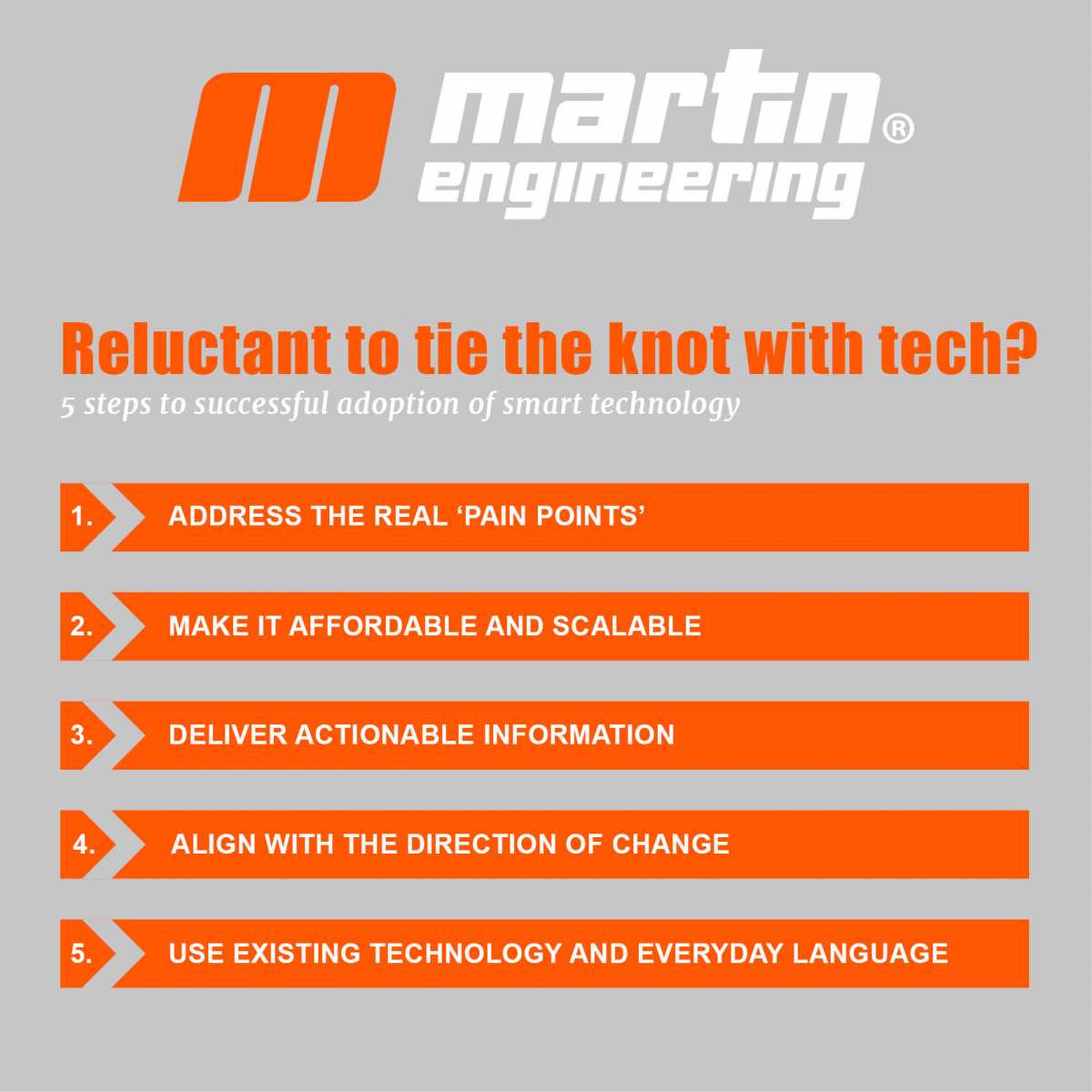

Are you afraid to tie the knot with tech? Smart technology is optimising almost every industrial sector. So why are some of us still reluctant to commit? In his latest blog Martin Engineering Vice President Robert Whetstone reflects on the development of the pioneering N2® remote monitoring and pinpoints 5 key steps to successful adoption of smart technology:

Martin’s N2® system for conveyor belt cleaners reduces safety risk, saves time and effort, and improves budgeting and inventory control by sending actionable performance data directly to your mobile device via an easy-to-use app or desktop dashboard. It’s like a fitness tracker for your belt cleaners! Successful customer trials in the UK and USA mean that N2® is now preparing to launch across Europe, Middle East, Africa & India! If you want to maximise your productivity using remote monitoring and predictive maintenance then get in touch. |

|

PAIN POINTS! Addressing our customers’ real pain points was our top priority for the launch of our market-leading internet of things innovation for conveyor belt cleaners. After extensive research we can offer our customers a win-win business model courtesy of our new N2® remote monitoring system which achieves five key things:

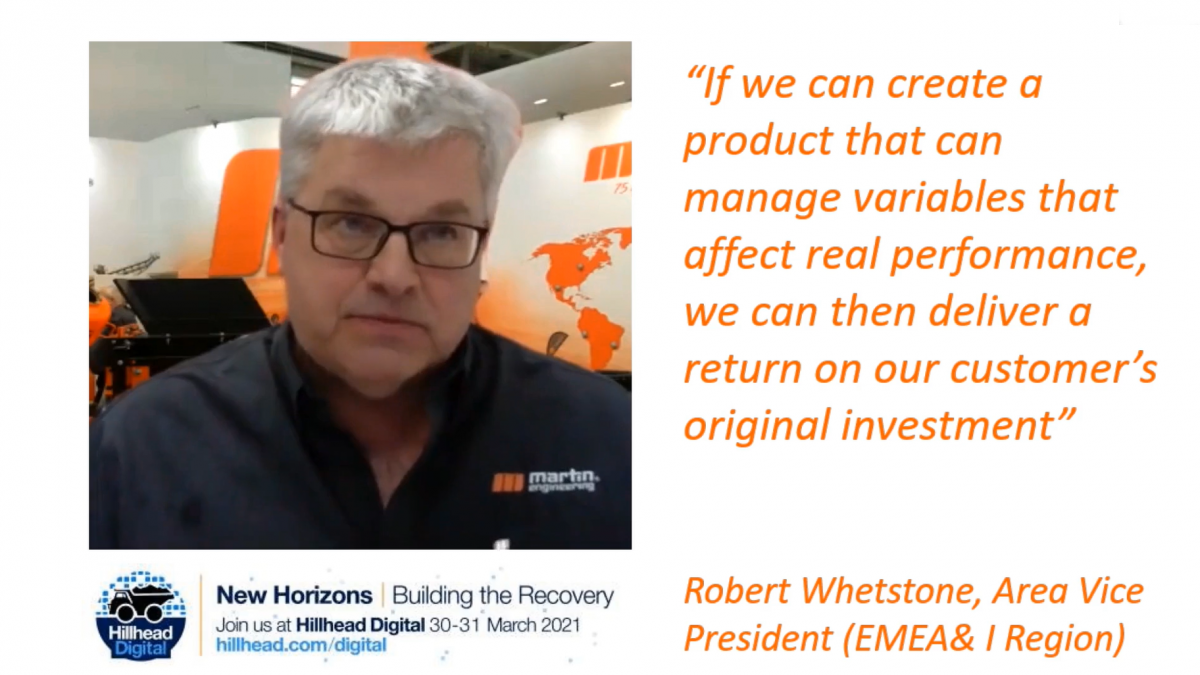

These areas were discussed in our recent presentation at Hillhead Digital from Martin Engineering Vice President Robert-Whetstone with Head of Sales & Marketing Valeria-Zimenkova. If you missed it you can watch it again here: |

|

Don’t ignore the Remote Revolution! Check out the new Quarry Management magazine where Martin-Engineering Vice President for EMEAI Robert Whetstone explains how to maximise productivity by using our innovative N2® remote monitoring system. “There’s a revolution happening right now in the mining and mineral processing industry that’s already giving companies competitive advantage – intelligent remote monitoring is driving new predictive, condition-based maintenance regimes.” Set to launch across Europe, Middle East, Africa and India during 2021, the N2® Position Indicator predicts when servicing is required and updates you via an easy-to-use mobile app. Read the full article and contact us to find out if you’re eligible for an exclusive pre-market trial at your plant. |

|

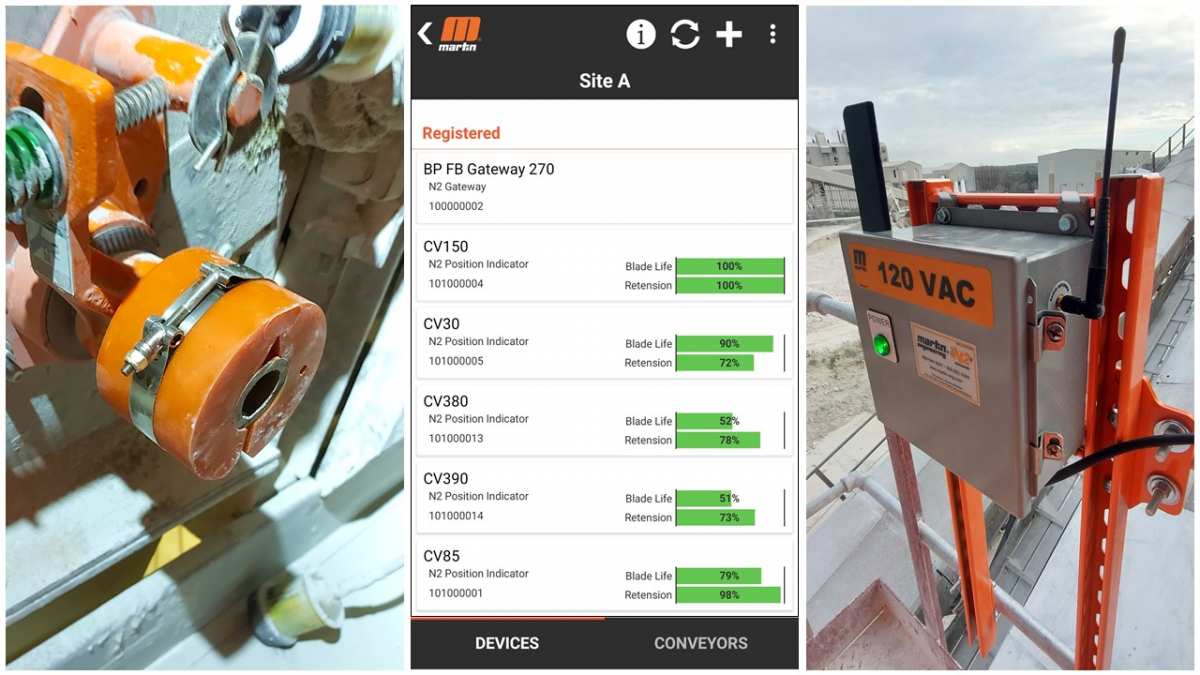

The results are in! The first customer trials of @Martin-Engineering’s pioneering N2® remote monitoring system are showing impressive results after two months. So much so that our customer is expanding the installation across their entire operation! The N2® Position Indicator is a #fitnesstracker for #conveyorbelt cleaners that predicts when servicing is required and updates you via an easy-to-use mobile app (pictured centre). It cuts out needless inspection visits, saves time and effort, improves maintenance safety, helps control costs and ultimately boosts productivity. N2® PI is launching in Europe, Middle East, Africa and India during 2021 – get in touch and take advantage before your competitors do! |

|

Martin Engineering conveyor belt cleaners control spillage and prevent unwanted material build-up so your processing plants run better for longer. And with our ground-breaking N2® Position Indicator (PI) system – launching very soon – your belt cleaners can be monitored remotely. Each N2 PI delivers belt cleaner performance data via the on-site ‘gateway’ to the cloud – from there it sends updates to your mobile device, predicting when to service or replace each cleaner blade. Using well-proven smart technology, the N2® PI reduces safety risk, saves time and effort, improves budgeting and helps with inventory control. Several N2 PI’s are already delivering performance data at one of the UK’s biggest chalk quarries and lime works, ahead of a major #productlaunch across Europe, Middle East, Africa and India from January 2021. Don’t miss the technology revolution! |

|

Successful installation of Martin Engineering’s ground-breaking N2® Position Indicator (PI) system in UK trials means that for the first time conveyor belt cleaners can be monitored remotely. Several N2 PI’s are now monitoring the condition of belt cleaner blades 24/7 at one of the UK’s biggest chalk quarries and lime works, ahead of a major product launch across Europe, Middle East, Africa and India in 2021. Easy to install and calibrate, every N2 PI delivers belt cleaner performance data via the on-site ‘gateway’ to the cloud – from there it’s sent to your mobile device, predicting when to service or replace each blade. Using well-proven smart technology, the N2® PI reduces safety risk, saves time and effort, improves budgeting and helps with inventory control. |

|

Martin Engineering service teams have installed our smart-yet-simple N2® Position Indicator remote monitoring system for belt cleaners in EMEAI for the first time. Trials are underway at one of the UK’s biggest chalk quarries and lime works – with almost 90 conveyors across the site they’re sure to benefit from our smart technology! Already proven in the USA, the N2® PI reduces safety risks, saves time and effort, improves budgeting and helps with inventory control. Automatically receiving data for every belt cleaner directly to your desktop or mobile device means you know exactly when to service or replace each blade. Next week we’ll show you more from the first installation and update you on how the system is performing during its UK debut. |