Our products keep biomass fuels moving efficiently and safely through your power plant, terminal and processing facility.

In today’s rapidly developing world, the global demand for alternative energy continues to grow at a fast pace. At the same time, more and more pressure is put on energy producers to develop sources for renewable energy. Biomass fuel is one of the most viable options in renewable energy because, in addition to providing an alternative to fossil fuels, much of the material used to make the fuel would otherwise end up in a landfill.

While the basic process for converting biomass fuel into energy is similar to coal and other fuels, transporting it through the process can be challenging. Primarily, this is because many types of biomass contain a high moisture and ash content, which means it sticks to belts and accumulates in chutes, hoppers and containers. Over time, a complete blockage can form and grind production to a halt, which is not just a drag on profitability, but also a safety issue because someone has to manually eliminate the obstruction, often resulting in "hammer-rash" and impulsive and dangerous employee efforts.

At Martin Engineering, our engineers and technicians have been leading the way when it comes to helping our customers adapt to transporting biomass materials and handling ash byproducts. For example, our belt cleaning products are known throughout the world as the absolute best in the business, which is critical when working with challenging materials like forest products, waste and agricultural byproducts. At the same time, some biomass fuels – like many energy crops and waste from the timber industry and forestry maintenance – contain little moisture and can form airborne dust, which causes health and safety problems.

Biomass processing involves dealing with a complex set of variables that includes moisture content, particle size and even humidity, allowing even the local weather to impact your operations. Unlike coal, which doesn’t vary much from load to load, there are many types of biomass fuels consisting of organic byproducts that are often mixed in with non-organic agricultural and residential waste, which makes for very inconsistent conditions. Whether your plant burns pre-processed biofuels or have to process its own biomass, our products will make your conveyor equipment and ash-handling systems more efficient at dealing with the variety of materials, while helping it last longer by reducing wear and tear. And, because the potential for shifting variables is always present, we recommend you contact a Martin Engineering representative to discuss your facility's specific conditions.

Biomass processing involves dealing with a complex set of variables that includes moisture content, particle size and even humidity, allowing even the local weather to impact your operations. Unlike coal, which doesn’t vary much from load to load, there are many types of biomass fuels consisting of organic byproducts that are often mixed in with non-organic agricultural and residential waste, which makes for very inconsistent conditions. Whether your plant burns pre-processed biofuels or have to process its own biomass, our products will make your conveyor equipment and ash-handling systems more efficient at dealing with the variety of materials, while helping it last longer by reducing wear and tear. And, because the potential for shifting variables is always present, we recommend you contact a Martin Engineering representative to discuss your facility's specific conditions.

While biofuels may be a relatively new way to generate electricity, Martin has a long history of working with power plants. Today, we are global experts in best practices when it comes to moving bulk materials. In fact, thousands of customers throughout the world rely on our belt cleaning and transfer point products to ensure that their conveyors are working at the highest possible capacity.

So, if you’re burning biofuels at your plant and having problems keeping the belts clean or shutting down to clean up blockages and fugitive dust, give us a call. We have been in business since 1944, so any problem you may be dealing with is probably something we’ve already solved! Our engineers and technicians are the best in the business and are dedicated to helping you improve your business, so contact a Martin representative today.

- Move material more efficiently along conveyor belt systems and minimize spillage and carryback

- Keep downtime for maintenance and housekeeping to a minimum

- Reduce spillage and equipment damage by keeping conveyor belts aligned

- Prevent material from spilling off moving conveyors

- Eliminate the need for workers to enter confined spaces

- Manage airborne dust and minimize the risk of explosion and inhalation

- Deliver more biofuel to your boiler safely and efficiently

- Reduce costs by minimizing fugitive material, including dust

- Eliminate excessive downtime for maintenance and belt cleaning

CleanScrape® Cleaner Improves Operations At Rock Quarry

Martin® Hurricane Air Cannons Alleviate Ash Buildup

Dust Curtain Keeps Fugitive Material From Nearby Homes And Businesses

Free Engineering and Application Assistance

Our technicians have solved problems for people in your industry all over the world. Take advantage of our wealth of knowledge. Tell us about your situation today to learn how Martin can improve your performance, safety and bottom line - with no obligation. We want to ensure that you choose the right solution for your exact needs and we are willing to invest the time upfront to get it right the first time.

Contact Us Now

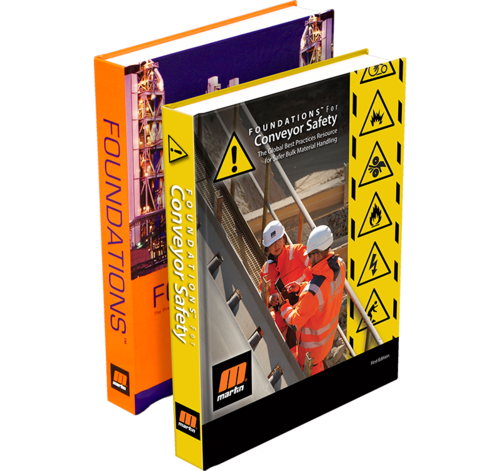

Foundations™ for Conveyor Safety

Learn to Calculate your Return on Conveyor Safety™ with our compilation of worldwide best practices for safer bulk material handling in this first-ever textbook dedicated exclusively to the safety of conveyor systems.

Request Your FREE PDF or Hard-Back Copy

Efficiently Remove Carryback on Both Vulcanized and Mechanically Spliced Belts

The CleanSCrape® Cleaner can last up to four times as long as traditional cleaners and can be used on belts with both mechanical and vulcanized splices. It lasts longer and cleans better, while using the lowest blade-to-belt pressure on the market. It is a revolutionary concept in belt cleaning technology that provides high performance with minimal wear and tear on belts.

See This Cleaner In Action and Understand the Difference Now

Save With Our Martin® Walk the Belt™ Service!

Every conveyor is different, even within the same facility! We can provide regularly-scheduled reviews of your bulk material handling system components, involving a specialized crew with the expertise necessary to achieve high operating standards, keeping the conveyor system running at maximum productivity. Immediate data and photos will be available to facility managers and our suggestions will ensure long-term savings and efficiency.

Get Your Belts Reviewed By People Who Know What They’re Looking At -- At No Charge!