Maintain and promote worker safety in your operation.

The health and safety of workers are everyone's highest priority, and the risk of injury or death from workers getting caught in rotating equipment or manually dislodging obstructions in material flow is always present. Additionally, dust suspended in the air from bulk solids like coal or cement can be inhaled by your workers, causing serious respiratory problems and other illnesses.

Clearly, protecting workers – and by extension, their families – from these dangers is the right thing to do. It’s also the financially responsible thing to do. In a plant where workers are not protected as part of the culture and strategy, the legal liability is much more severe. The potential for lawsuits goes up and the cost of insurance is higher. Plus, you run the risk of being fined by the government for safety violations.

With Foundations™ For Conveyor Safety, we have compiled all the proven best practices for keeping workers safe into a single textbook. That means you can literally talk about safety with the people who "wrote the book!" There's even a section in the book on how to demonstrate ROI for new safety initiatives.

If you are concerned about the safety of your workers and feel that you could do more to protect them, talk to one of our experts. We’re standing ready to listen to you describe your operation and offer recommendations on how to optimise your operation for better safety. Our team is available to provide expert advice and assistance on all of your bulk material handling questions and problems.

Conveyor Guards Drastically Reduce Risk Of Injury

Existing System Jeopardizes Output Capacity And Employee Safety

Filtrating Dust At Environmentally-Conscious Coal-Fired Power Plant

Air Cannons Dramatically Improve Employee Safety

Belt Cleaners Improve Safety and Efficiency At Cement Plant

Air Cannons Prevent Buildup on Kiln Walls

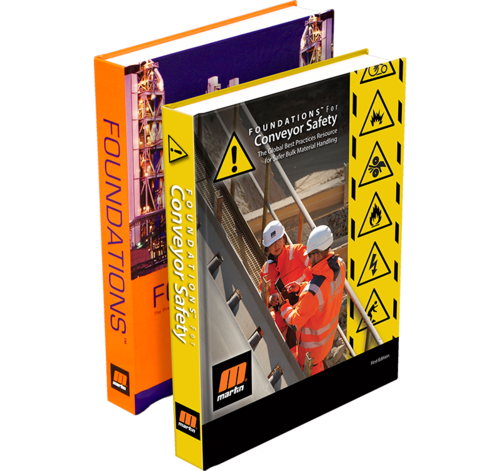

Foundations™ for Conveyor Safety

Learn to Calculate your Return on Conveyor Safety™ with our compilation of worldwide best practices for safer bulk material handling in this first-ever textbook dedicated exclusively to the safety of conveyor systems.

Request Your FREE PDF or Hard-Back Copy